3. Setting up the work environment

All required data and the prepared python modules are available in a gitlab repository: https://git.fh-aachen.de/lectures-material-wollert/oee_python_course

Todo

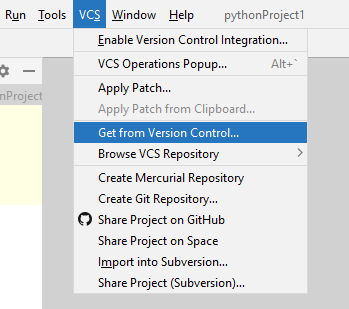

Fork and clone this repository (using HTTPS).

Todo

Check if all required libraries (see requirements.txt) have been installed automatically.

Therefore, go to Files -> Settings -> Project -> Python Interpreter.

If libraries are missing, you can manually install them using the + symbol.

Todo

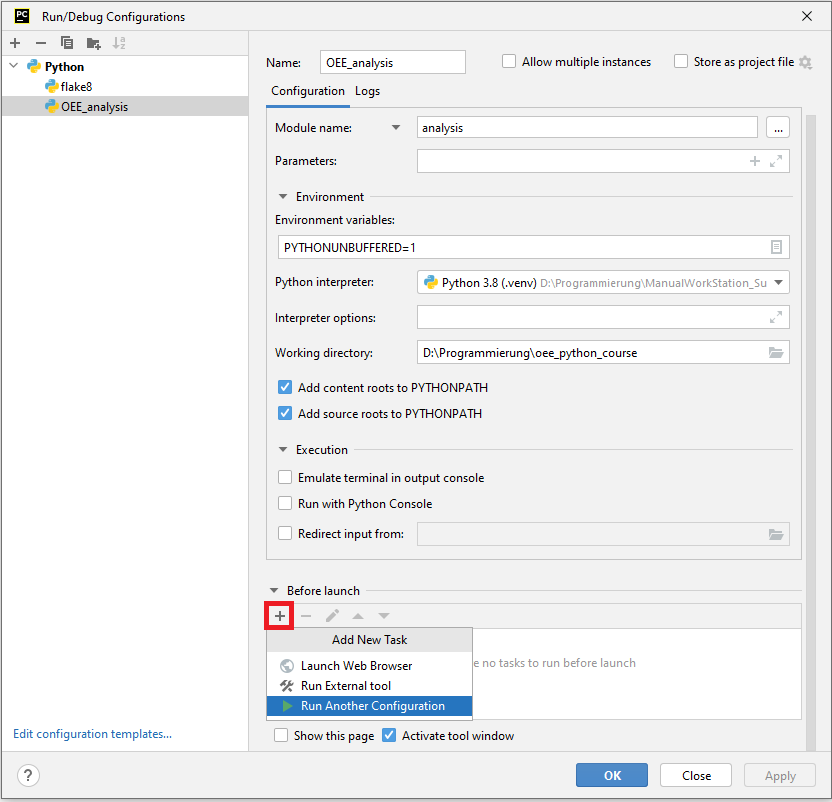

Add a new Python run configuration to start the program logic in PyCharm. Add your module (here: analysis.py) to the configuration. Set the working directory to your project folder.

Todo

Check if the main function is executed when you start the configuration (the logger should show an AssertionError: The function ‘get_dataframe_from_directory’ has no return value).

(The assertion error is thrown as the function get_dataframe_from_directory is not yet implemented.)

Todo

Include style checking using flake8 to make your program more readable.

Add the module which should be checked in Parameters.

Set the working directory to your project folder.

Todo

You can automatically check your programming style before executing the main program logic by adding the flake8-configuration to your main configuration.

Todo

Check if the work data is in your project repository.

4. Understanding the work data

The MWS of the Industry 4.0 model factory displays situation-dependent work instructions and detects user interactions. It consists of

A height-adjustable working desk on which instructions can be projected,

A storage area with a pick-by-light system,

A tool holder and two acknowledgment buttons, and

A Poka-Yoke workpiece holder for assembly operations.

The work sequence consists of 20 work steps in which parts must be mounted or clipped to form an industrial handgrip of the company Item Industrietechnik GmbH. One tool, a screwdriver, is required for the assembly execution. First, the side parts of the handgrip are premounted twice and placed in a storage box. Afterward, these side parts are attached to the main profile, and the covers are placed over the screws.

In order to reduce the assembly complexity and simplify the small parts handling, a workpiece holder is used. The workpiece holder consists of 3D-printed parts, which limit the mounting options. This way, unintended errors are prevented (Poka-Yoke principle).

The manual workstation is capable of detecting the majority of user interactions automatically:

A LiDAR sensor is used to capture grabbing actions in the storage area.

The tool holder identifies if a tool is available or not.

The workpiece holder checks if the workpieces are placed in the correct positions.

Also, two check positions are integrated, ensuring all covers are placed correctly, and the side areas are mounted tightly.

As the cover clipping cannot be identified automatically, these work steps must be acknowledged manually by pressing a hand or foot button. In order to evaluate the user interactions, the system stores all interactions on a granular basis, including user id, timestamps, durations, run number, and correctness.

For a user study, over 60 test persons were asked to assemble the handgrip five times at the MWS. The participants had different backgrounds, from mechatronics to psychology.

Todo

Check the provided work data in your project repository (folder workdata).

Each number (501-5xx and 601-6xx) represents a test user who was requested to manufacture the handgrip five times.

The node specifies the name of a work step according to a given work sequence. For instance, the work sequence starts with a work step (node) called “Place_Nut_1” followed by “Place_Holder_1”. Each work step can include several user interactions, such as picking a nut and placing it afterwards.

The “DefaultTime” specifies an initial approximation of working times according to the performance of ten initial users.

In this project, the goal is to analyze the obtained work data according to productivity and quality; the main focus is on the Overall Equipment Effectiveness (OEE). In this application example, the different working days should be analyzed and compared.

As the work data was obtained during a user study, no traditional working shifts were used but time slots (60min) during which the participants had to assemble the handgrip five times but also answer some questionnaires. The starting time of the planned working slots were noted in a .csv file

Todo

Check out the planned work slots planned_working_times.csv